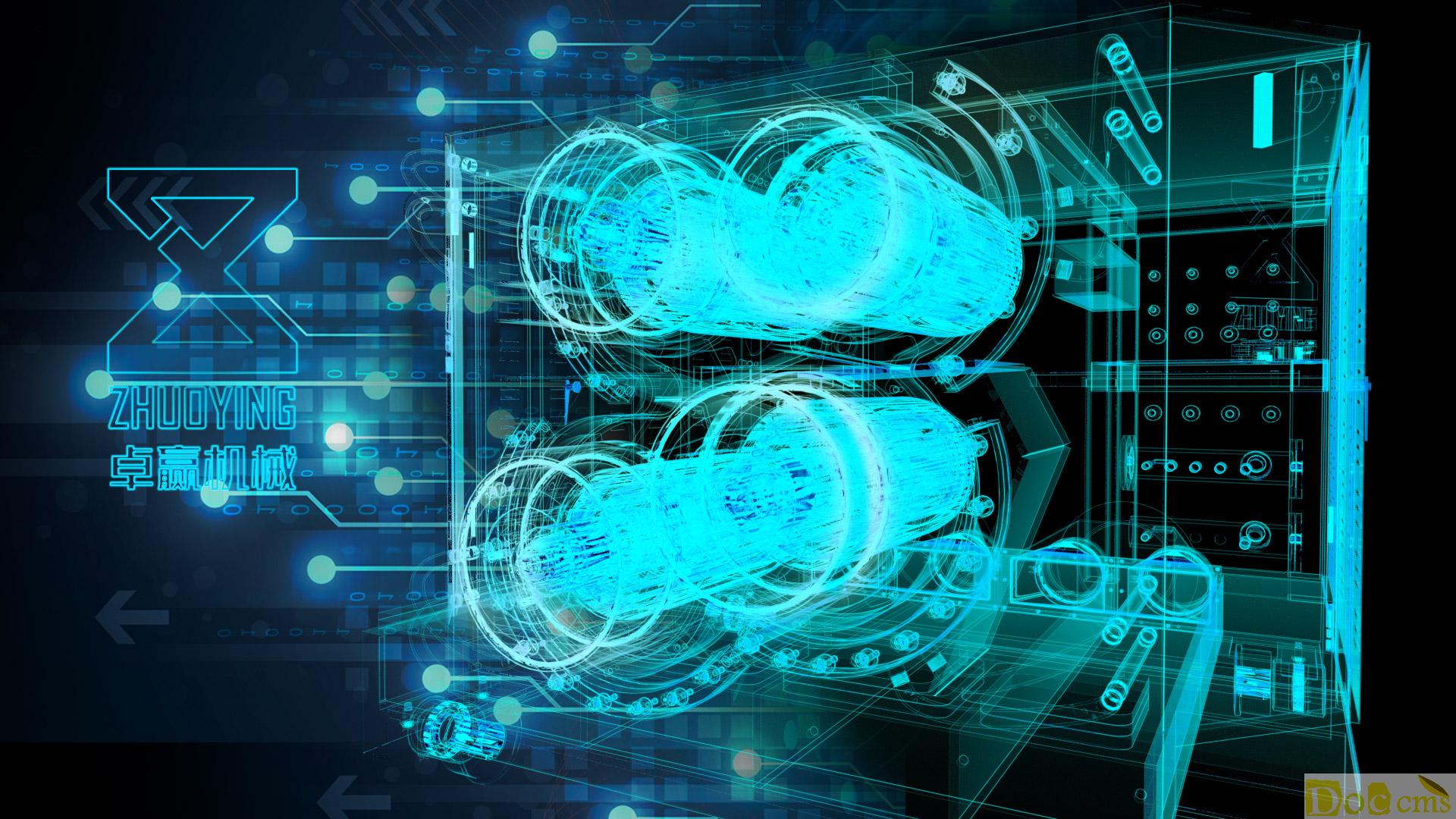

Big Data Intelligent Predictive Diagnosis of Rock Wool Centrifuges

In today's era of advanced artificial intelligence and big data, these cutting-edge technologies are transforming every aspect of industry. The trend towards datafication and intelligentization across the entire industry chain is accelerating. Zhuoying, in the rock wool centrifuge manufacturing industry, also deeply understands the trend and necessity of mechanical intelligence. Zhuoying has accumulated a large amount of production line operation data and hopes to leverage this valuable data to help solve early warning and diagnostic mechanisms for centrifuge maintenance and malfunctions, specifically involving the following aspects:

-

Data Acquisition and Sensor Installation: Various sensors are installed on the rock wool centrifuge to monitor key parameters such as rotational speed, temperature, vibration, and current. These sensors continuously collect data during the equipment's operation.

-

Data storage and integration: The collected data needs to be stored and integrated for subsequent analysis. This can be achieved through a cloud platform or a local database, ensuring data security and accessibility.

-

Data preprocessing: The collected data may contain noise and outliers, so preprocessing is required, including data cleaning, noise reduction and outlier handling, to ensure data quality.

-

Feature extraction: Extracting useful features from the collected raw data. For example, extracting efficiency, material loss, and time correlation from rotational speed data, and extracting temperature change trends corresponding to operating time from temperature data. These features can help build fault diagnosis models.

-

Establish a fault diagnosis model: Utilize technologies such as machine learning and deep learning to establish a fault diagnosis model. The model can learn the normal operating modes of the equipment based on historical data. When the collected data is inconsistent with the model's predictions, it may indicate that the equipment has malfunctioned.

-

Model Training and Optimization: The model is trained using historical data, and its parameters are optimized. This process requires a large amount of machine operation data and front-line production data. The richness of the data and the fine-tuning of the model's parameters will greatly improve the accuracy and stability of predictions.

-

Real-time monitoring and analysis: Sensors continuously collect real-time data during rock wool centrifuge operation. This data is analyzed using models to predict potential equipment failures or maintenance needs. Extensive manual adjustments are required initially to ensure the model provides more accurate diagnostic results.

-

Fault warning and alert: If the model detects an anomaly, the system will generate a fault warning and send an alert to notify relevant personnel to take measures, such as maintenance, repair or shutdown of the equipment.

-

Maintenance plan development: Based on the results of fault warnings and predictions, develop corresponding maintenance plans. This may include specific repair work, parts replacement, etc.

-

Effectiveness Evaluation and Optimization: For predicted failure scenarios, conduct an effectiveness evaluation after actual maintenance, and deploy the system in a front-line trial run to collect more data, while continuing to fine-tune the data. This helps optimize the model and maintenance strategy, improving the accuracy and reliability of predictions.

By combining parameter monitoring with intelligent big data analytics, rock wool centrifuges can achieve predictive maintenance, anticipating potential failures and maintenance needs, thereby reducing downtime and repair costs, and improving equipment availability and production efficiency. This requires the comprehensive application of domain expertise, data analysis techniques, and engineering practices beyond machining, marking a tentative step in introducing big data into the centrifuge manufacturing industry.

Zhuoying hopes to inspire others to join hands in looking to the future and working together to realize the "Made in China 2025" initiative.