Zhuoying 350 helps rock wool enterprises save energy and increase efficiency.

In recent years, rock wool production enterprises have faced high costs, which continue to rise.

From 2020 to 2021, the pandemic comprehensively impacted the global economy, with most developed economies adopting loose monetary policies to cope with its effects. The combined effects of production disruptions and excessive money supply have led to soaring global commodity prices, causing global enterprise production costs to rise accordingly. Cost reduction and efficiency improvement have become top priorities for enterprises.

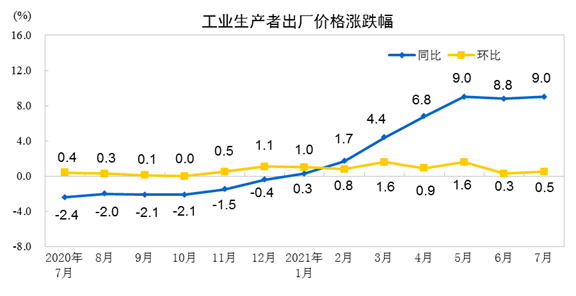

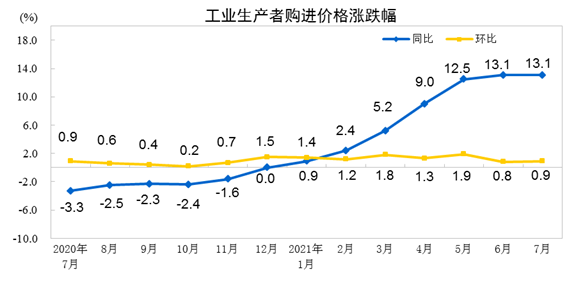

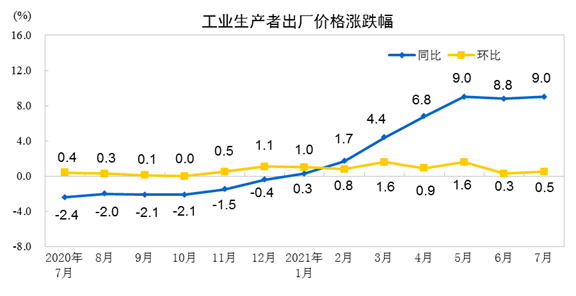

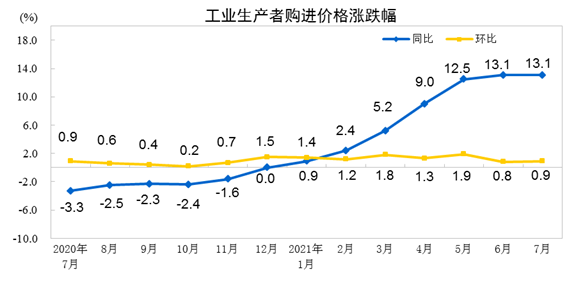

The rock wool industry is currently facing similar difficulties. In July 2021, the national industrial producer price index (PPI) rose 9.0% year-on-year and 0.5% month-on-month; the industrial producer purchase price index (PPI) rose 13.1% year-on-year and 0.9% month-on-month. From January to July, the average PPI rose 5.7% compared to the same period last year, and the PPI rose 7.9%.

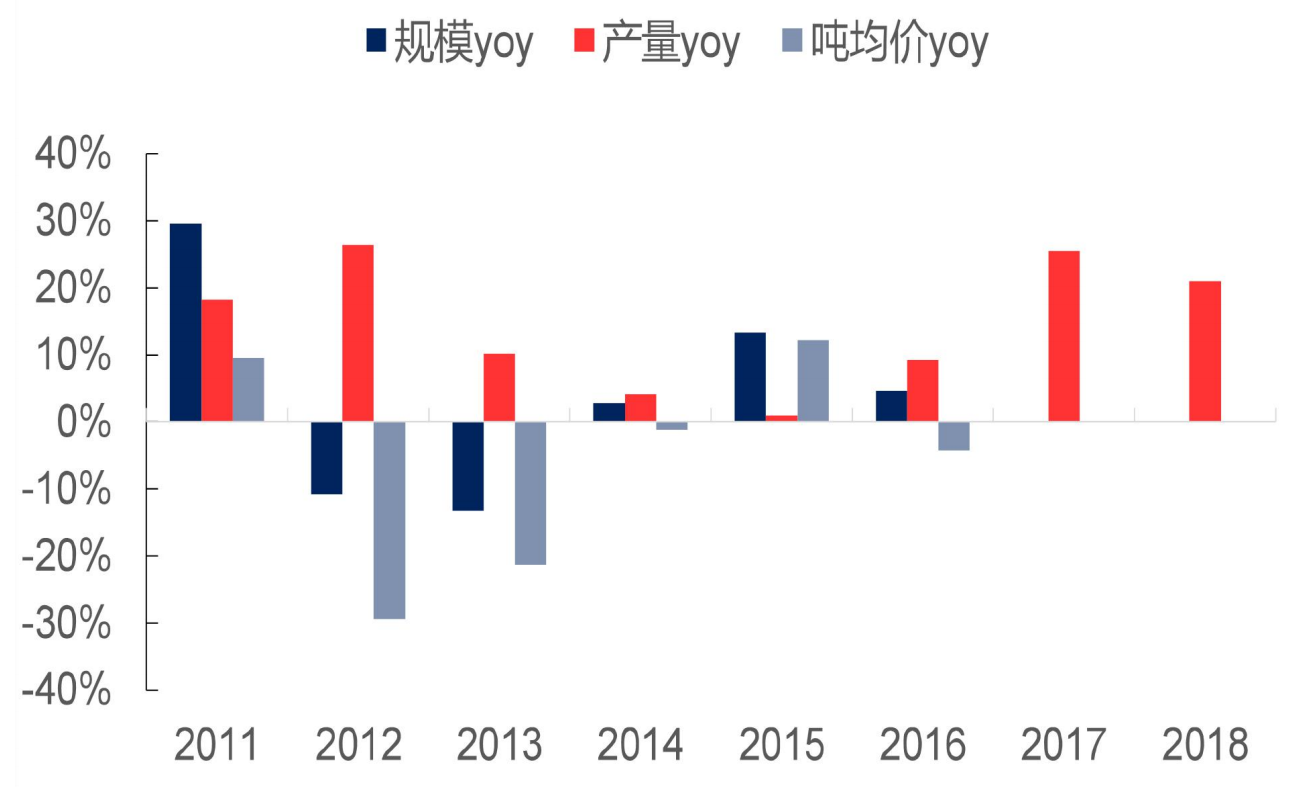

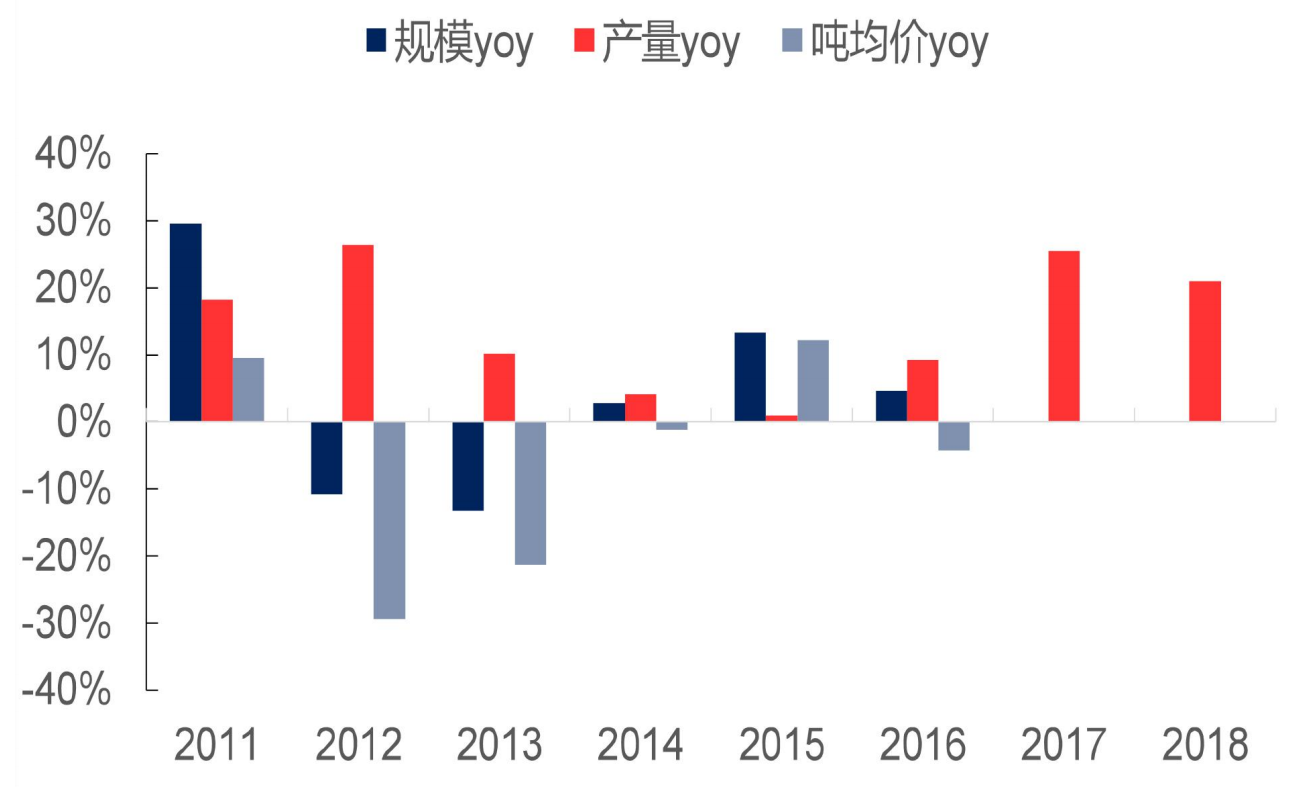

Overcapacity

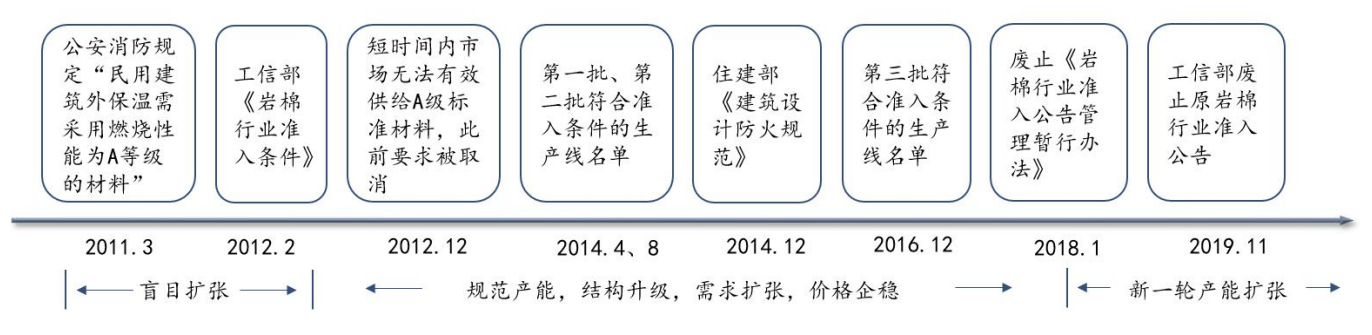

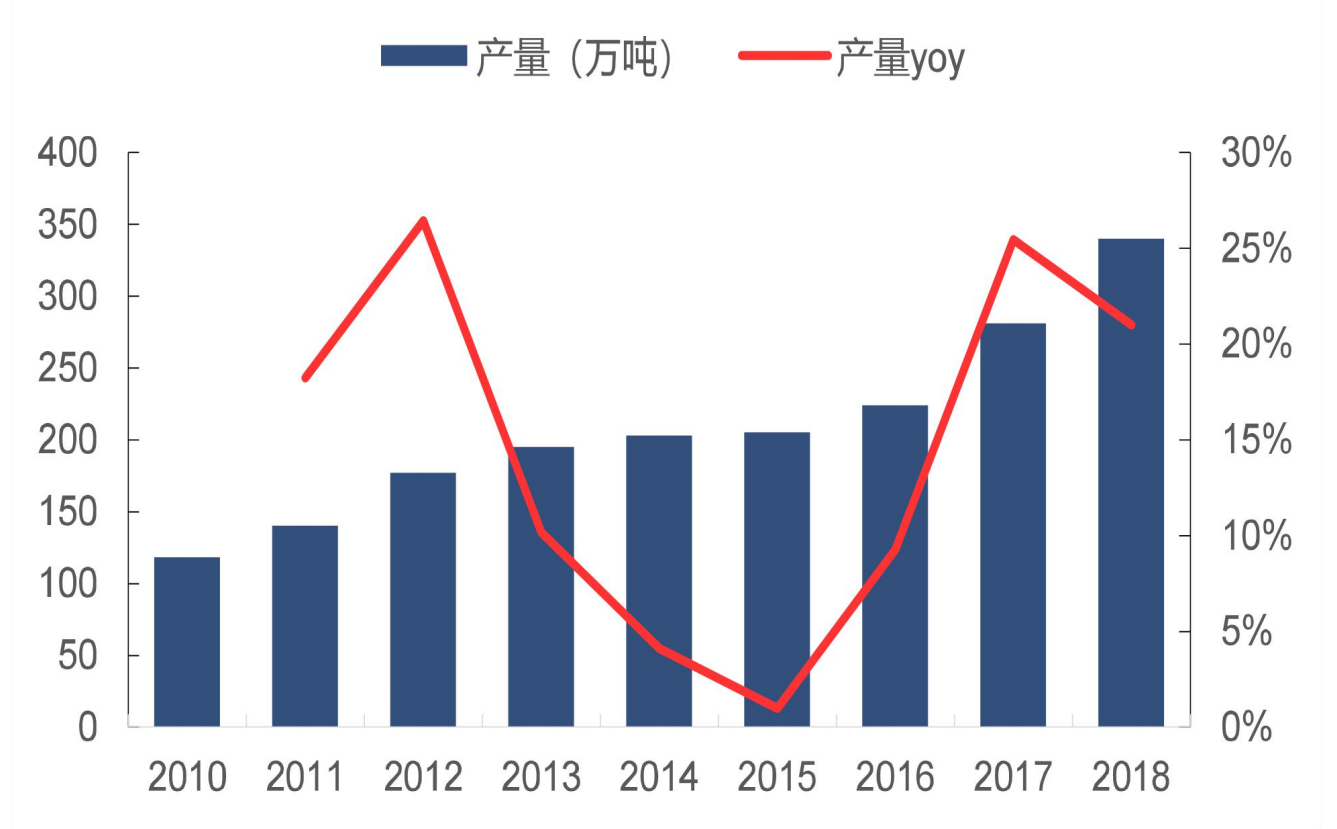

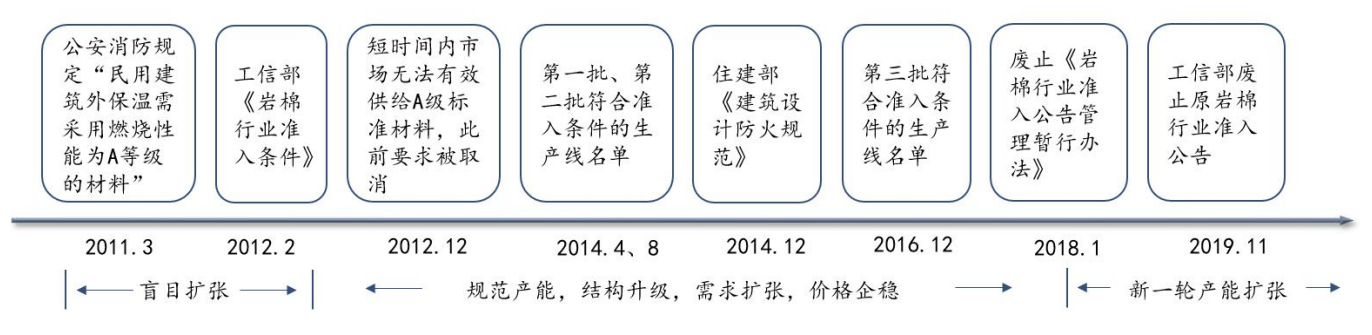

, supply-demand imbalance, and high price pressure are also present challenges for the rock wool industry. In January 2018, the "Interim Measures for the Administration of Rock Wool Industry Access Announcements" were repealed, and in November 2019, the "Rock Wool Industry Access Conditions" were repealed. Based on the relaxation of industry access conditions and optimistic market expectations, rock wool entered a new round of capacity expansion.

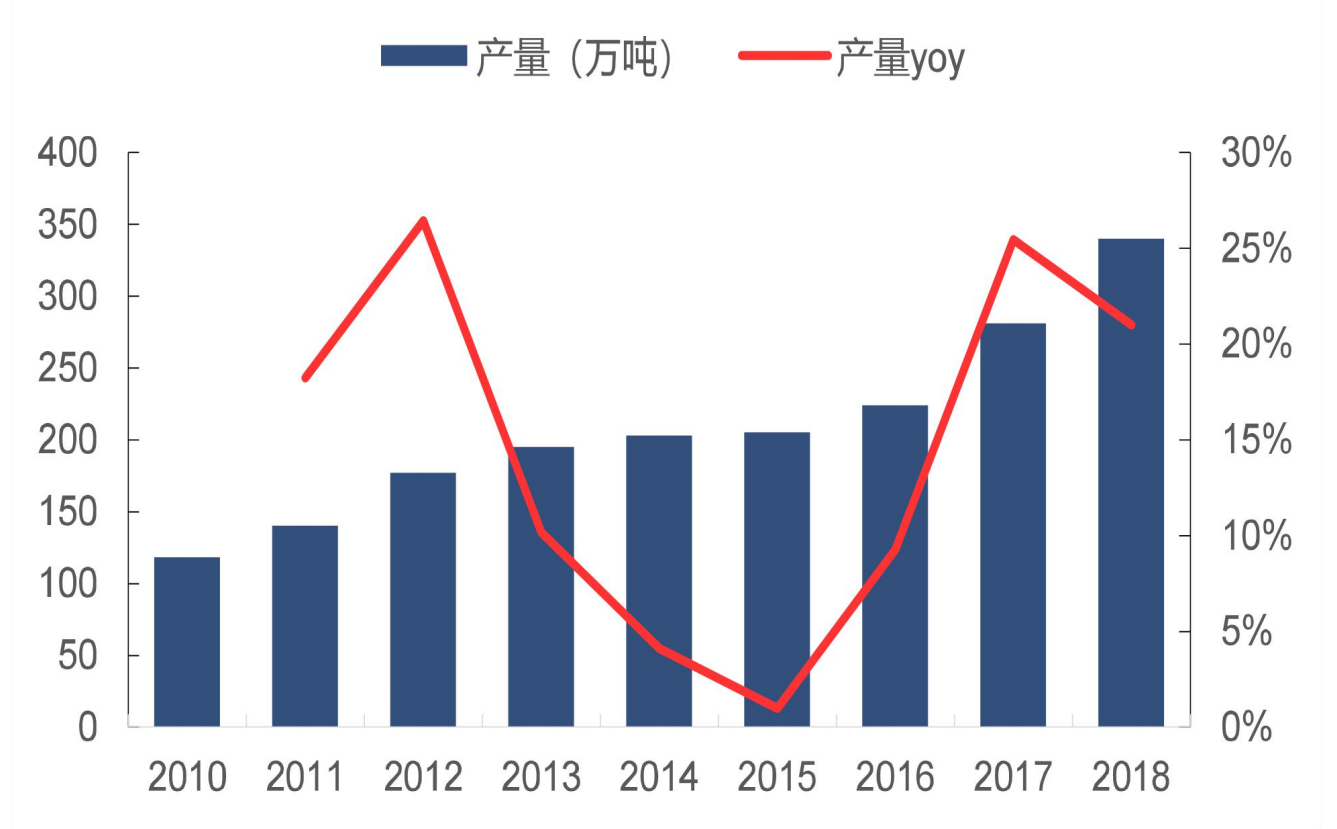

According to data from the China Thermal Insulation and Energy Saving Materials Association, in 2019, China's total rock wool production capacity was 7.5 million tons, with an output of approximately 3.2 million tons. The average capacity utilization rate was less than 50%, leaving considerable room for growth before reaching full capacity. Most enterprises experienced unsatisfactory economic benefits, and the industry's supply-demand imbalance is expected to continue for a considerable period. On

the one hand, production costs have risen sharply; on the other hand, the supply-demand imbalance limits the potential for price increases, creating the current predicament in rock wool production. How to control costs and increase efficiency to ensure profit margins has become crucial for rock wool producers to overcome these difficulties. Zhuoying

's Cost Control and Efficiency Improvement Solution

Zhuoying—as the designated industry R&D center of the Thermal Insulation and Energy Saving Association—has the responsibility and mission to contribute to the industry.

As a professional R&D manufacturer of rock wool centrifuges, Zhuoying offers its own solution: the Zhuoying 350 four-roller fiber-forming center glue spraying centrifuge.

The Zhuoying 350 adopts a new generation of level-two energy-saving motors, increasing output power while reducing energy consumption, achieving cost reduction and production increase in one step.

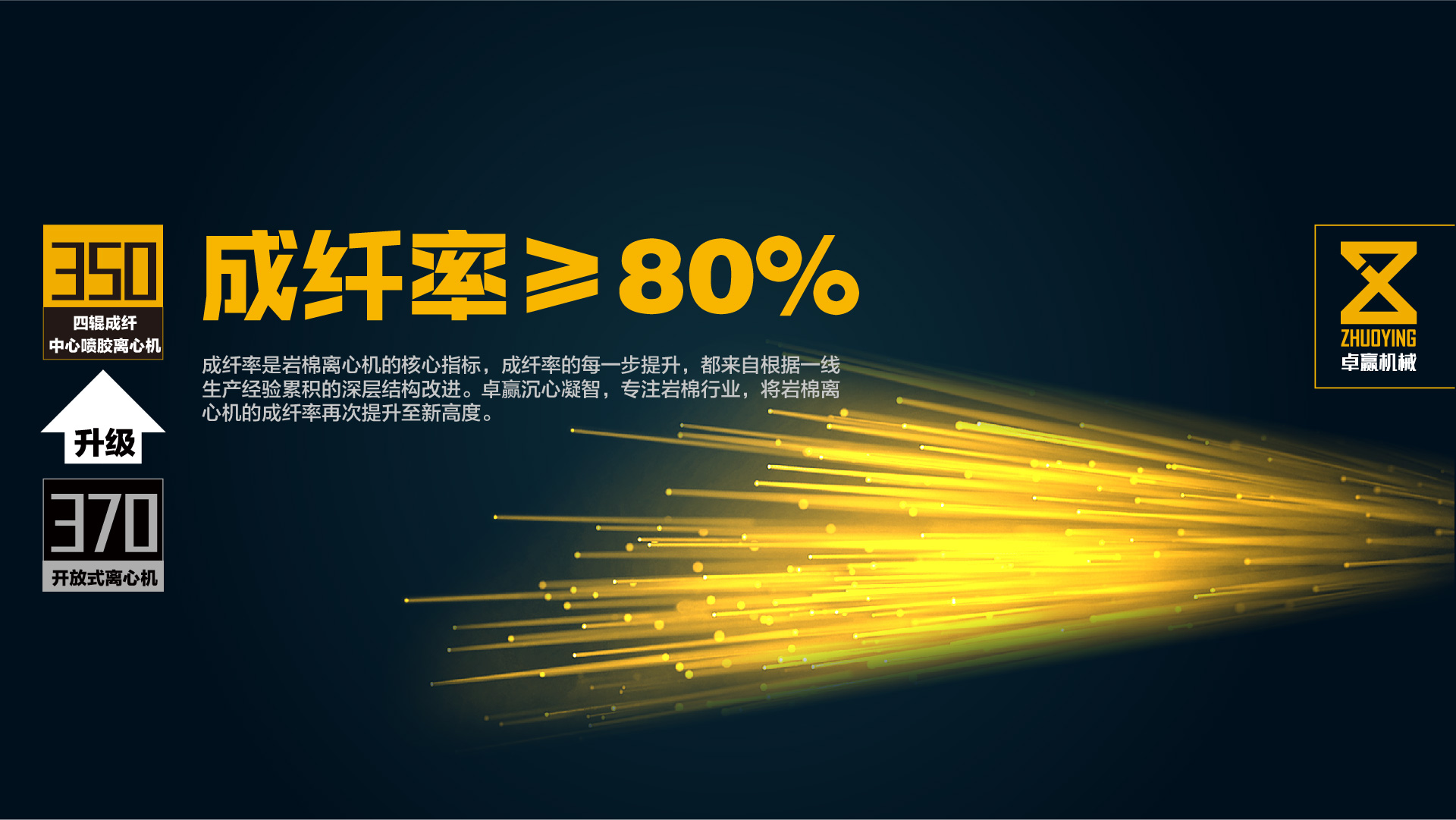

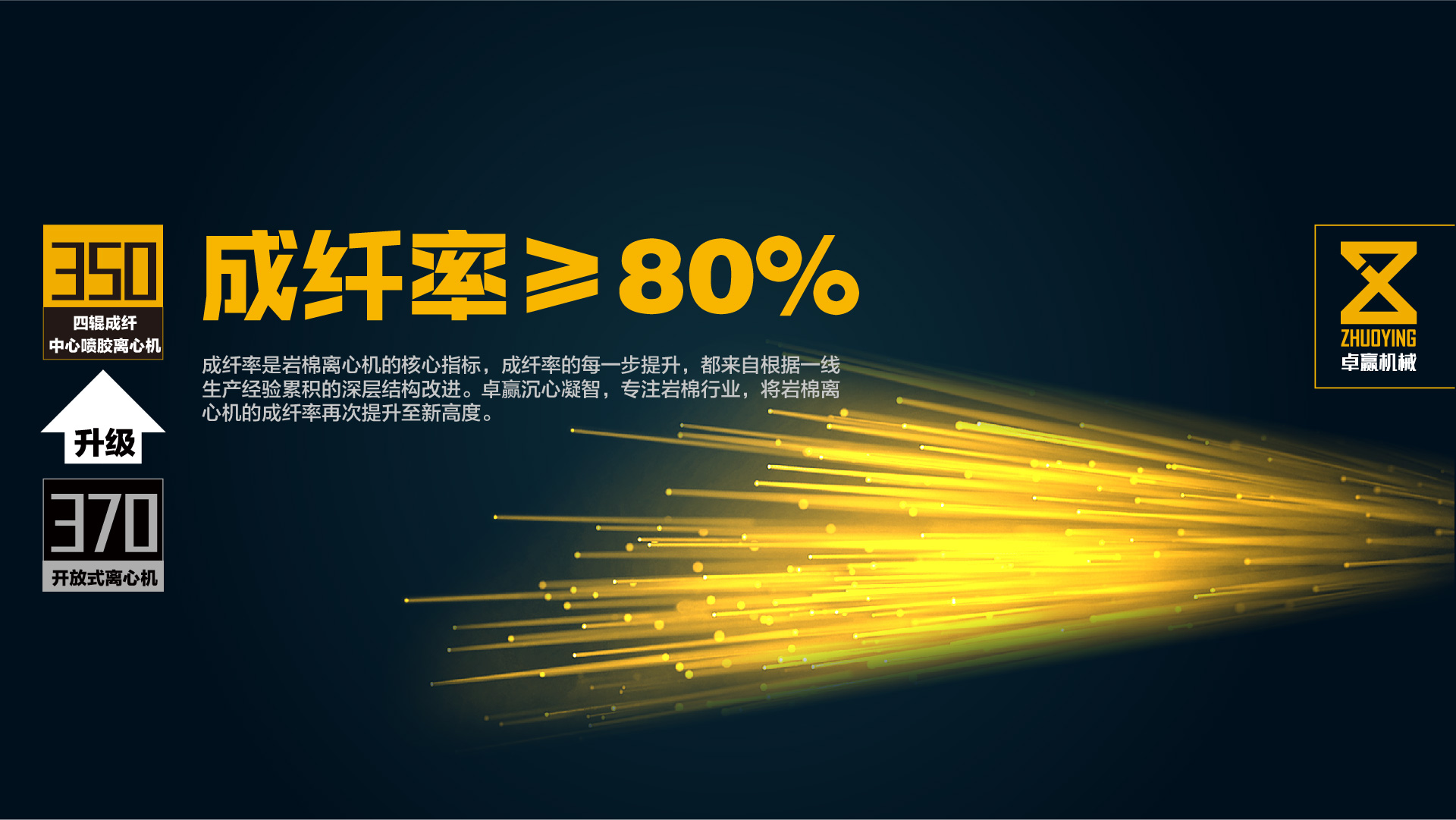

Through a comprehensively improved roller structure and precision-designed transmission accuracy, the fiber formation rate of rock wool production is further increased to 80%, resulting in higher output and significantly improved efficiency under the same time and raw material conditions.

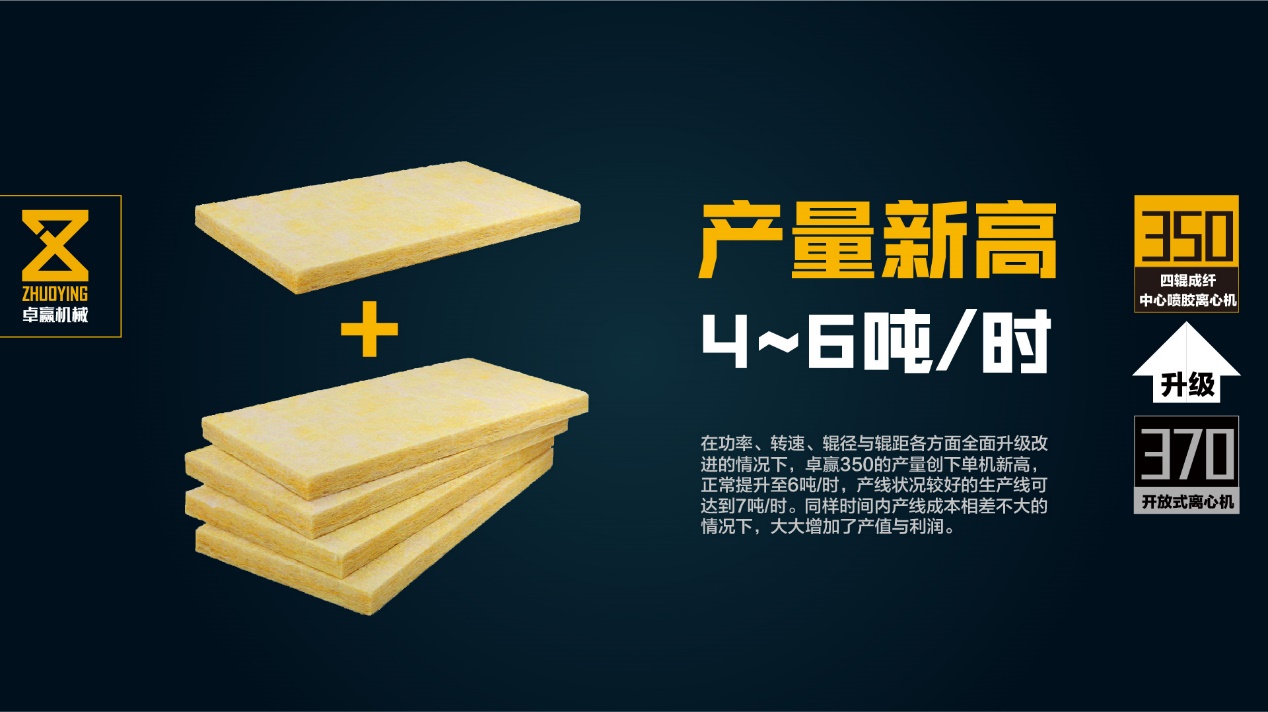

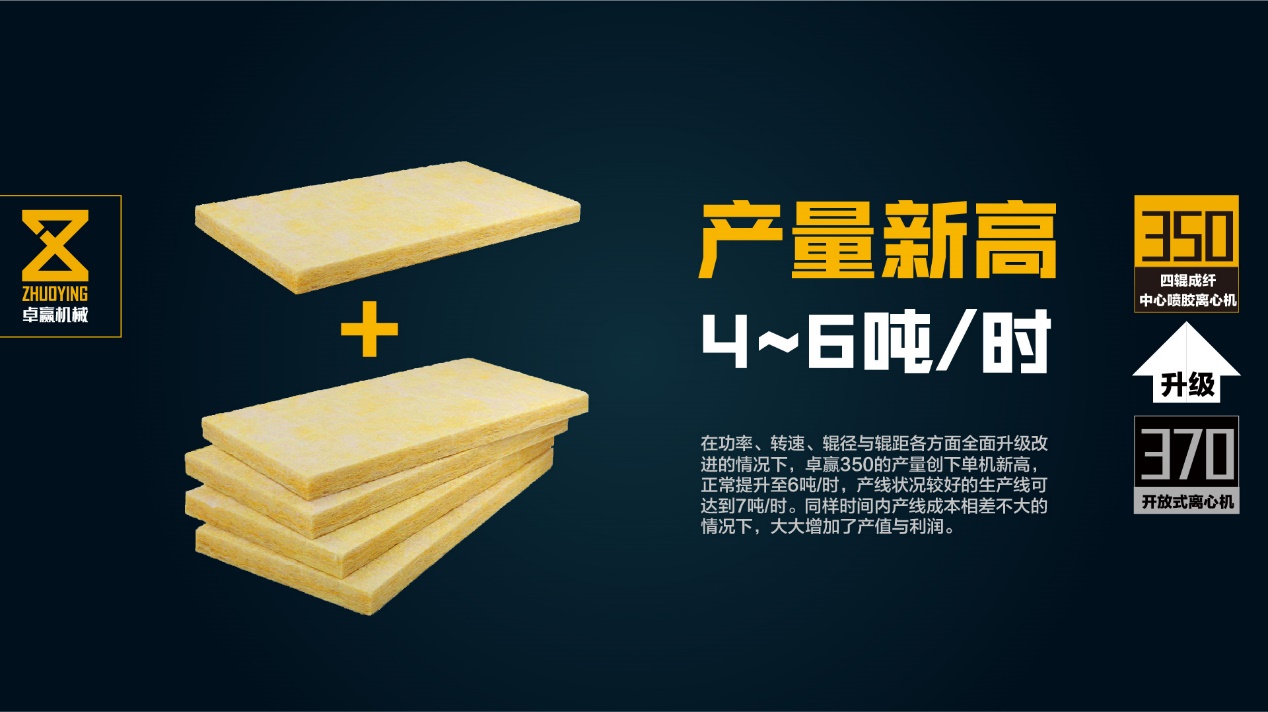

With comprehensive upgrades and improvements in power, speed, roller diameter, and roller spacing, the Zhuoying 350 has achieved a new high output per machine, normally reaching 6 tons/hour, and up to 7 tons/hour on well-performing production lines.

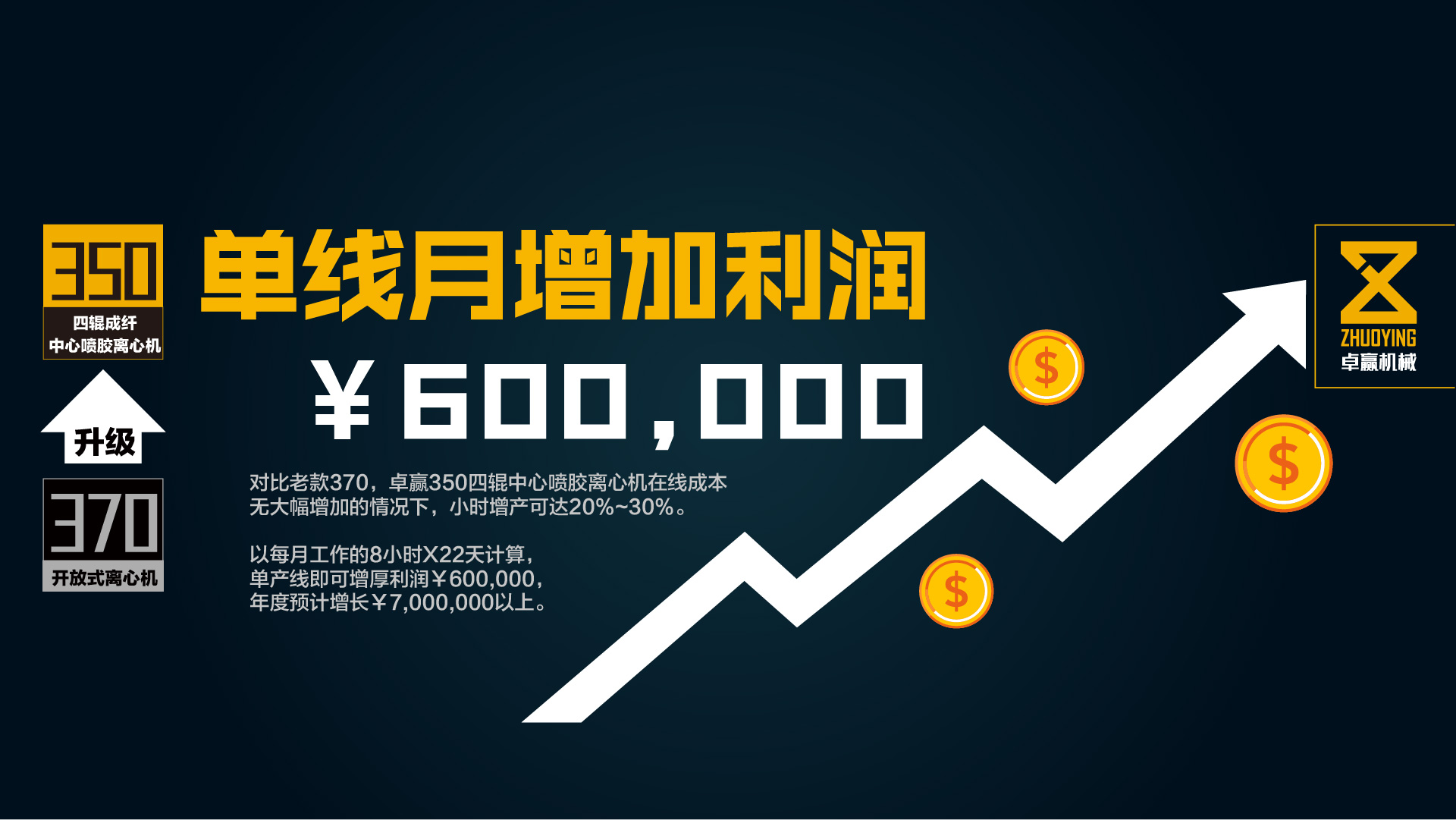

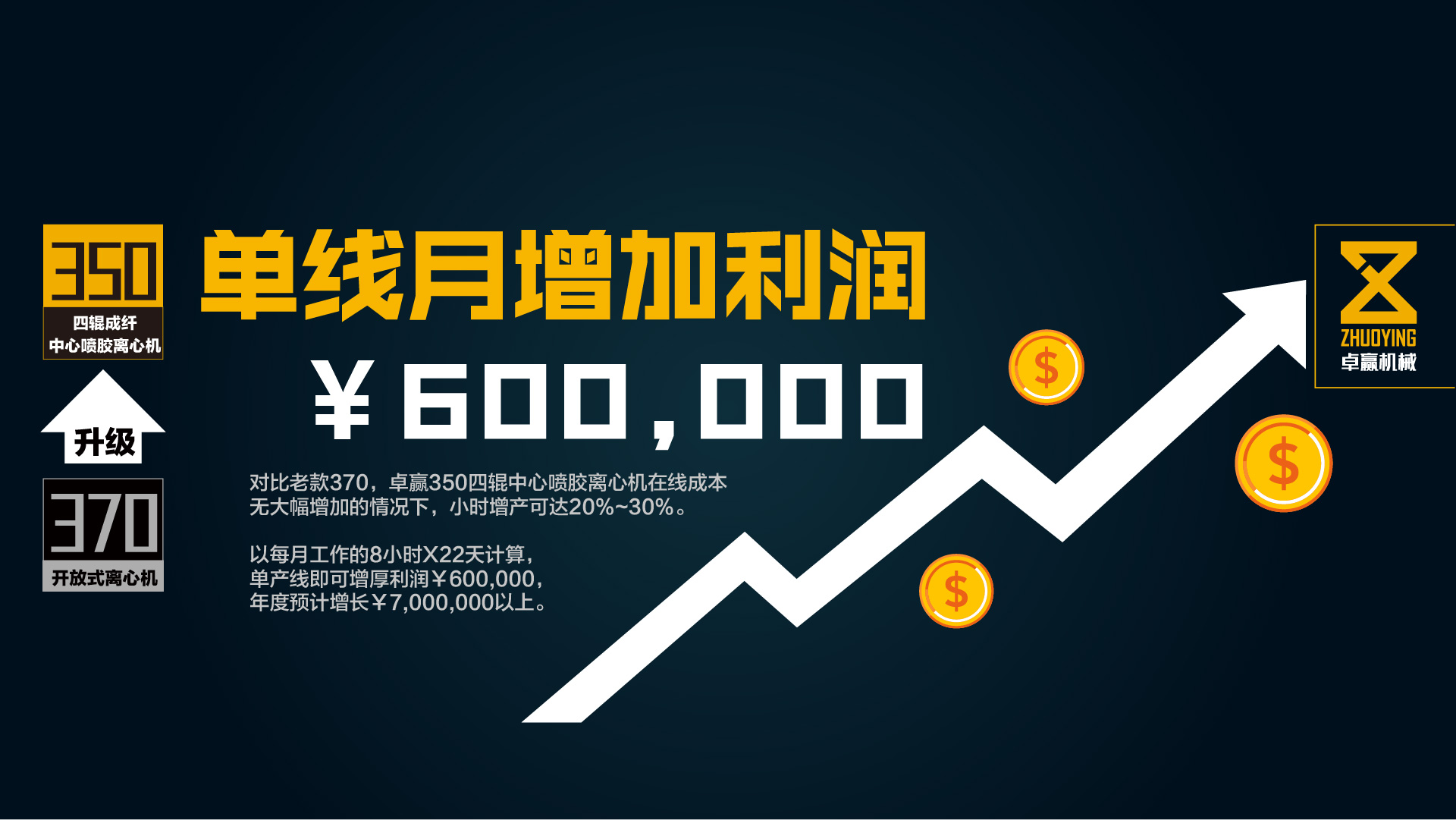

After replacing the previous generation of rock wool centrifuges with the Zhuoying 350 and adding it to the production line, the profit margin of the rock wool production line has changed significantly due to increased production and efficiency, as well as energy saving and consumption control.

Calculated based on 8 hours of work per month x 22 days,

a single production line can increase profits by ¥600,000, with an estimated annual increase of over ¥7,000,000.

It is widely acknowledged in the industry that rock wool centrifuges involve not only significant initial purchase costs but also substantial maintenance and repair expenses. Zhuoying's 350 utilizes a multi-wedge belt flexible connection, tailored to domestic usage conditions, resulting in a more rational structure, easier operation and maintenance, lower maintenance costs, and simpler upkeep. This further helps companies save costs and improve efficiency, thereby increasing production and productivity.

Zhuoying, having established itself in the industry with its 370 series, has received guidance and feedback from numerous leading industry experts. With years of accumulated experience, Zhuoying has dedicated itself to developing the new generation 350 rock wool centrifuge, hoping to further exchange ideas with the industry on cost control and efficiency improvement in rock wool production lines. With a commitment to the industry, Zhuoying strives for progress and works together with its peers.

From 2020 to 2021, the pandemic comprehensively impacted the global economy, with most developed economies adopting loose monetary policies to cope with its effects. The combined effects of production disruptions and excessive money supply have led to soaring global commodity prices, causing global enterprise production costs to rise accordingly. Cost reduction and efficiency improvement have become top priorities for enterprises.

The rock wool industry is currently facing similar difficulties. In July 2021, the national industrial producer price index (PPI) rose 9.0% year-on-year and 0.5% month-on-month; the industrial producer purchase price index (PPI) rose 13.1% year-on-year and 0.9% month-on-month. From January to July, the average PPI rose 5.7% compared to the same period last year, and the PPI rose 7.9%.

Overcapacity

, supply-demand imbalance, and high price pressure are also present challenges for the rock wool industry. In January 2018, the "Interim Measures for the Administration of Rock Wool Industry Access Announcements" were repealed, and in November 2019, the "Rock Wool Industry Access Conditions" were repealed. Based on the relaxation of industry access conditions and optimistic market expectations, rock wool entered a new round of capacity expansion.

According to data from the China Thermal Insulation and Energy Saving Materials Association, in 2019, China's total rock wool production capacity was 7.5 million tons, with an output of approximately 3.2 million tons. The average capacity utilization rate was less than 50%, leaving considerable room for growth before reaching full capacity. Most enterprises experienced unsatisfactory economic benefits, and the industry's supply-demand imbalance is expected to continue for a considerable period. On

the one hand, production costs have risen sharply; on the other hand, the supply-demand imbalance limits the potential for price increases, creating the current predicament in rock wool production. How to control costs and increase efficiency to ensure profit margins has become crucial for rock wool producers to overcome these difficulties. Zhuoying

's Cost Control and Efficiency Improvement Solution

Zhuoying—as the designated industry R&D center of the Thermal Insulation and Energy Saving Association—has the responsibility and mission to contribute to the industry.

As a professional R&D manufacturer of rock wool centrifuges, Zhuoying offers its own solution: the Zhuoying 350 four-roller fiber-forming center glue spraying centrifuge.

The Zhuoying 350 adopts a new generation of level-two energy-saving motors, increasing output power while reducing energy consumption, achieving cost reduction and production increase in one step.

Through a comprehensively improved roller structure and precision-designed transmission accuracy, the fiber formation rate of rock wool production is further increased to 80%, resulting in higher output and significantly improved efficiency under the same time and raw material conditions.

With comprehensive upgrades and improvements in power, speed, roller diameter, and roller spacing, the Zhuoying 350 has achieved a new high output per machine, normally reaching 6 tons/hour, and up to 7 tons/hour on well-performing production lines.

After replacing the previous generation of rock wool centrifuges with the Zhuoying 350 and adding it to the production line, the profit margin of the rock wool production line has changed significantly due to increased production and efficiency, as well as energy saving and consumption control.

Calculated based on 8 hours of work per month x 22 days,

a single production line can increase profits by ¥600,000, with an estimated annual increase of over ¥7,000,000.

It is widely acknowledged in the industry that rock wool centrifuges involve not only significant initial purchase costs but also substantial maintenance and repair expenses. Zhuoying's 350 utilizes a multi-wedge belt flexible connection, tailored to domestic usage conditions, resulting in a more rational structure, easier operation and maintenance, lower maintenance costs, and simpler upkeep. This further helps companies save costs and improve efficiency, thereby increasing production and productivity.

Zhuoying, having established itself in the industry with its 370 series, has received guidance and feedback from numerous leading industry experts. With years of accumulated experience, Zhuoying has dedicated itself to developing the new generation 350 rock wool centrifuge, hoping to further exchange ideas with the industry on cost control and efficiency improvement in rock wool production lines. With a commitment to the industry, Zhuoying strives for progress and works together with its peers.